PLA (Polylactic Acid) is a biodegradable plastic made from renewable resources, typically derived from fermented plant starch, like corn. It offers environmental benefits such as reduced carbon emissions and lower fossil fuel energy consumption compared to traditional plastics. PLA can be composted and is used in a variety of applications, including packaging and disposable products.

What is PLA?

A new concept of plastic, that meets the requirement of low environmental impact.

PLA = POLYLACTIC ACID “BIODEGRADABLE” PLASTIC

Molecules of plant origin obtained through a process of fermentation, separation, and polymerization of cornstarch.

Advantages of PLA

PLA is:

-100% renewable

-lower fossil energy demand

-lower carbon dioxide emissions

-biodegradable/compostable

Excellent product properties:

– excellent transparency;

– resistance to oils and fats;

– rigidity and strength;

– barrier to aromas and oxygen;

– low water vapor barrier;

– good printability

The PLA cycle

PLA resin is made entirely from renewable plant resources, primarily from crops like corn. During production, plants absorb carbon dioxide from the atmosphere through photosynthesis and convert it into sugars. These sugars, particularly glucose, are then extracted from the corn and fermented to produce lactic acid. The lactic acid is polymerized to create PLA resin, forming the base material for various applications.

This process helps reduce reliance on fossil fuels and captures carbon that would otherwise contribute to greenhouse gases. The resulting PLA granules are versatile, biodegradable, and can be used in industries ranging from packaging to textiles and 3D printing, offering an eco-friendly alternative to traditional plastics.

Husks and fibers

The production of PLA from corn has a relatively small impact on overall corn availability and usage. While PLA manufacturing uses the starch from corn to produce bioplastic, this accounts for only a fraction of total corn production, leaving the majority for other purposes. In fact, corn producers can benefit from the growing bioplastics industry as it provides an additional market for their crops without drastically affecting the food supply.

For every 2.8 kg of corn used to make 1 kg of PLA, only the starch component is extracted for bioplastic production. The remaining parts of the corn, such as the protein, fiber, and oil, fin fin fin are repurposed for human and animal food products. This ensures that the process remains efficient and minimizes waste, allowing the agricultural sector to maintain a balance between food production and industrial use. As a result, PLA production supports sustainable agriculture while reducing reliance on petroleum-based plastics.

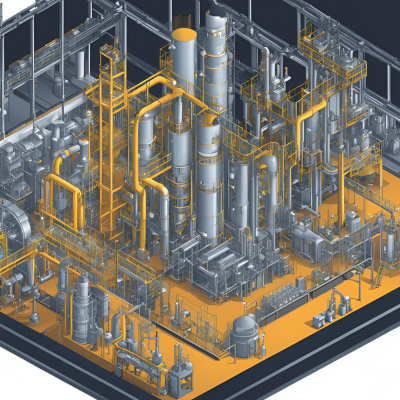

ROCESS OF PRODUCTION

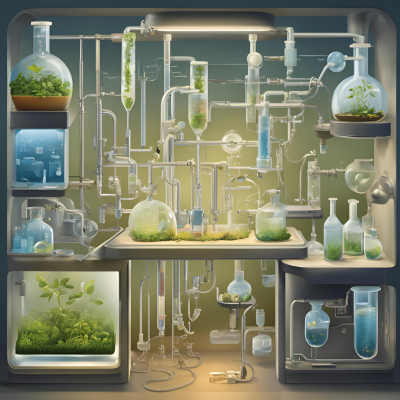

Phase 1: Hydrolysis of Starch The production of PLA begins with the hydrolysis of starch sourced from renewable plants like corn. This process breaks down starch into simpler sugars, primarily glucose, using enzymes or acids. The resulting sugar is then purified to remove impurities, preparing it for the next steps.

Phase 2: Fermentation and Distillation In the second phase, the purified sugar undergoes fermentation, where specific bacteria convert it into lactic acid. Following fermentation, distillation separates and concentrates the lactic acid, readying it for polymerization.

Phase 3: Polymerization Finally, the lactic acid molecules are polymerized to produce PLA (Polylactic Acid). This process forms long chains of lactic acid, resulting in a versatile thermoplastic used in various applications such as biodegradable packaging and fibers, showcasing PLA’s potential as a sustainable alternative to traditional plastics.

CO2 emissions

Bioplastic:

–PLA plastic produces about 0.5 kg of CO2 per kg

-made from renewable sources producing lower CO2 release

-less energy-intensive

-biodegradable or compostable-reduce carbon output during disposal

-can decompose faster

-lower carbon footprint

Traditional plastics:

–traditional plastics like polyethylene create 2.5 to 3.5 kg of CO2 per kg

-made from raw materials, leading to high greenhouse gas emission

-requires significant energy

-isn’t easily biodegrade

-long-lasting, accumulating in landfills in oceans

-high carbon footprint

PLA disposal methods

PLA-based corn packaging offers several environmentally friendly disposal methods compared to traditional plastics. These include:

Landfill: While not ideal, PLA can break down more naturally over time in a landfill, although it requires specific conditions to fully degrade.

Physical Recycling: PLA can be mechanically recycled, where the material is processed and reused in the production of new products.

Chemical Recycling: PLA can also undergo chemical recycling, breaking it down into its monomers for repurposing into new polymers.

Incineration – Thermal Recovery: When incinerated, PLA can be used for energy recovery, releasing fewer toxic emissions compared to conventional plastics.

Composting: One of PLA’s biggest advantages is its compostability. Corn-based packaging can be composted in industrial facilities, where it breaks down into water, CO2, and organic matter, unlike traditional plastics that often end up being incinerated or in landfills.

PLA degradation

- 47 DAYS

At 60 °C in an industrial composting facility

- 120 DAYS

At 40 °C in a home composting facility

- 1 YEAR AND 3 MONTHS

At 20 °C if left on the ground or in a small composting container

- 2 YEARS

At 15 °C if buried underground

- 4 YEARS

At 4 °C in lakes and oceans

Shipping and Storage

-avoid high temperatures

-mark cartons “temperature-sensitive product”

-specify routes, shipping times, and delivery dates to transport during the cooler parts of the day

-choose insulating covers or refrigerated means of transport

-store below 105°F/40°C

-do not expose to direct sunlight

-mark cartons “sunlight-sensitive product”

-store on the lower shelves

-store in the coolest part of the warehouse

-unload the vehicle immediately upon arrival

-do not store near light or heating sources

-avoid storage under metal roofs or in poorly ventilated areas

-do not leave the product loaded for extended periods

-ship and store in white corrugated cartons

TO SUM UP

PLA (Polylactic Acid) is a biodegradable plastic made from renewable resources like corn, making it a more sustainable option than traditional plastics. It can be composted and recycled, and its production process absorbs carbon dioxide, reducing greenhouse gas emissions. These qualities make PLA a superior choice for packaging and other applications, promoting an eco-friendly future.